Welcome! Deal Once ..

Our mission is to provide creative support that help Industies to get the best Price.

We provide our scrap collection services to construction site, factory clearance, warehouse/store, metal collection, demolition contractors and collections, scrap metal removal and site clearance. We pay top prices for copper, cable, brass, aluminium, stainless steel, mild steel, lead, various cables, electric motors, all type of iron and steel, etc.

Explore! Price Deals with Live Martket Value...

-

Price for types of plastic

High-Density Polyethylene (HDPE); Polyvinyl Chloride (PVC); Low-Density Polyethylene (LDPE); Polypropylene (PP); Polystyrene or Styrofoam (PS)

-

Even used and Garbage Plastic

Polyethylene(PE).Low-Density Polyethylene(LDPE).Medium-Density Polyethylene(MDPE).High-Density Polyethylene(HDPE).Ultra High Molecular Weight...

-

Injection Moulding Runners

The runner is the channel that feeds directly into the gate of each part. If the Injection Mold only has one cavity then there will only be one branch to the

-

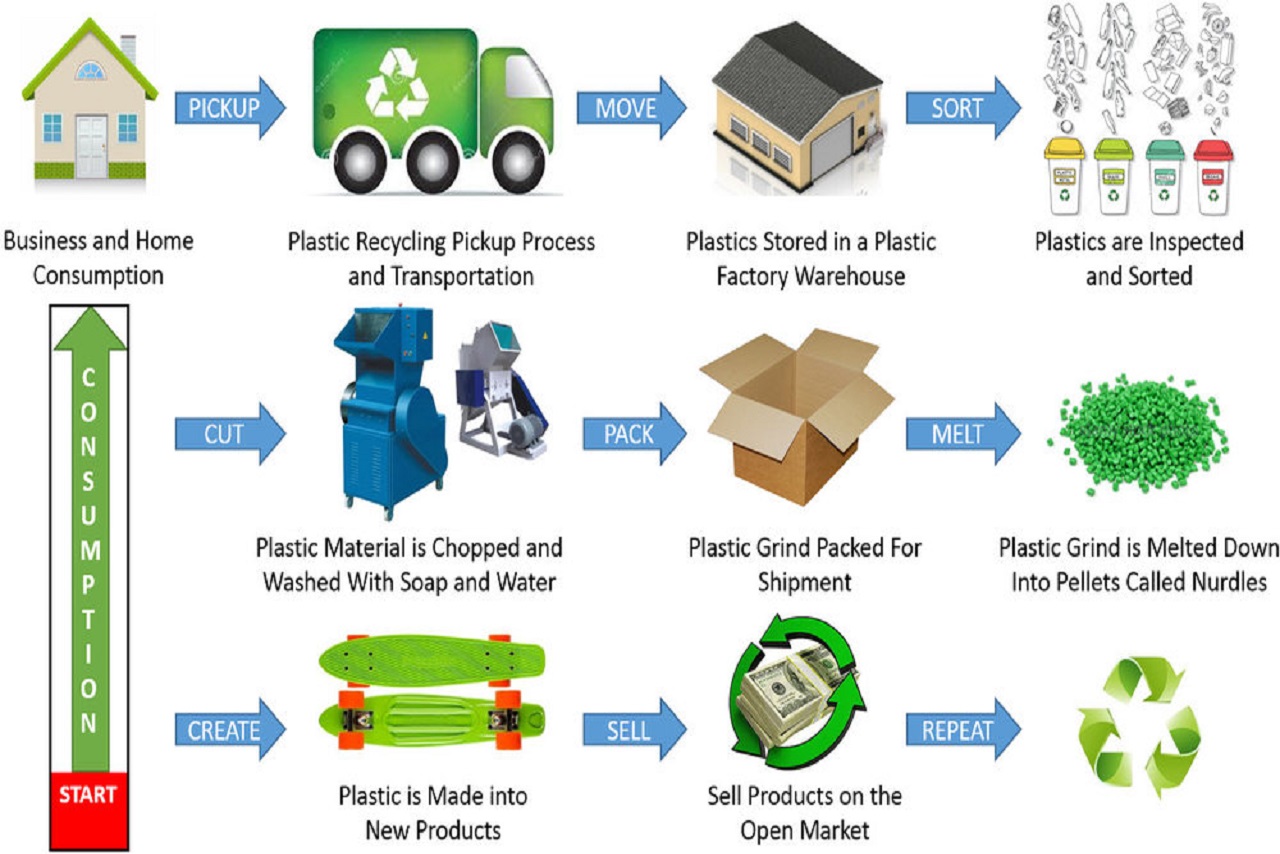

Recycling Procedure

Involves shredding of the waste into flakes. After shredding, the plastic flakes are soaked in hot water to eradicate contaminants. Involves heating the plastic to a melting point so that it can be processed into granules.

What We Do?

We Recycle all Industrial Waste...

Our Mission is to serve industries and Clean all there machine generated scrap waste in a formal way .

LIVE RATES

MANAGEMENT

TRADING

SERVICE

PAYMENTS

We Process Services

Loading Sorting Melting...

- CREATION

- ANALYSIS

- STRATEGY

Spot a place where you can get a deal for your scrap metal on fair terms, such as a nearby scrapyard. When you bring the metal, separate them according to their type. You can use a magnet if required. You can now bring the metal to the scrap yard for weighing in. Some scrap dealers run curbside recycling services and scrap metal collectors services for your convenience.

Scrap yards separate materials through visual identification, magnets, electric current, and spectrometer. Products with mixed metals need to be dismantled to obtain different metals and materials.The scrap metal is ordered in particular weight, size, and shape. The scrapyard prepares the metal by torching, shredding, or baling to size and processes it according to the order received by the customer.

Melting and refining is the process of separating impurities from the metal. The impurities rise to the top through melting. Some metals require additional refining, like electrolysis. This purifying process makes the metal as good as its parent metal. The metal is solidified after the purification through melting and refining. It is solidified according to the shape required for the end product. It can be sheets, coils, bars, etc. In some metals, chemicals are added to make them denser or change their properties.

Long Term Deals

Total Deals

Processing Deals

Witness Our Work

No Fraudalents...

- All

- Category1

- Category2

- Category3

- Category4

- Category5

We are now Competetive Company Around the Bangalore City to Major Industrial Areas.

Spreading Over Karnataka..

Get In Touch!

Call +91-9741777490

Subscribe to our newsletter and we will inform you about newest projects and promotions.